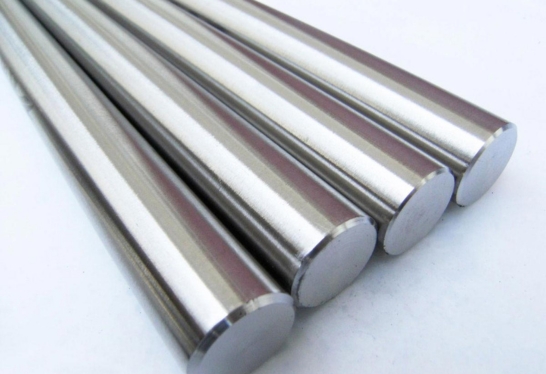

Hastelloy C22/C276 Round Bar

Two high-performance nickel-based alloys with exceptional corrosion resistance in severe environments are Hastelloy C22 and C276. These alloys are frequently employed in sectors like petrochemicals, chemical processing, and pollution control.

Leading suppliers of Hastelloy C22 and C276 Round Bars include Mannat Steel. To satisfy the unique needs of various applications, these round bars are offered in a variety of diameters and dimensions.

A versatile nickel-chromium-molybdenum-tungsten alloy called Hastelloy C22 Round Bar has good resistance to stress corrosion cracking, pitting, and crevice corrosion. This alloy is perfect for use in pulp and paper manufacturing, pollution control, and chemical processing.

Hastelloy C22/C276 Wire Rod

High-performance nickel-based alloys Hastelloy C22 and C276 are renowned for their remarkable corrosion resistance in a variety of harsh chemical conditions. These alloys are utilised in a variety of industries, including petrochemical, oil and gas production, and chemical processing.

A reputable source of Hastelloy C22/C276 wire rods is Mannat Steel. These wire rods can be customised to meet the unique needs of the customer and come in a variety of sizes and diameters. Hastelloy wire rods from Mannat Steel are constructed to withstand high temperatures and harsh situations using premium quality raw materials.

Hastelloy C22/C276 Wire

Two high-performance nickel-based alloys, Hastelloy C22 and C276 are utilised in a number of applications, including the production of wire. Hastelloy C22/C276 wire is supplied by Mannat Steel, whose goods are widely used in the chemical processing, aerospace, maritime and oil and gas sectors.

Nickel-chromium-molybdenum alloy Hastelloy C22 wire has excellent corrosion and oxidation resistance in both oxidising and reducing conditions. Additionally, it offers superb resistance to stress corrosion cracking, pitting, and crevice corrosion. Hastelloy C22 wire is frequently used in equipment for chemical processing, pollution control, the manufacture of pharmaceuticals, and the fabrication of synthetic fibres.

Hastelloy C276 wire is another nickel-chromium-molybdenum alloy that offers excellent corrosion resistance in a wide range of environments. It is particularly resistant to corrosion by chlorides, sulfur compounds, and oxidizing acids. Hastelloy C276 wire is commonly used in chemical processing, pulp and paper production, and waste treatment facilities.

Hastelloy C22/C276 Wire Mesh

Due to their outstanding resistance to a variety of corrosive conditions, Hastelloy C22 and C276 are two corrosion-resistant alloys that are frequently employed in wire mesh applications.

A nickel-chromium-molybdenum-tungsten alloy known as Hastelloy C22 provides remarkable corrosion resistance to a range of acids, including sulfuric, hydrochloric, and phosphoric acids. Additionally, it is immune to stress corrosion cracking, pitting, and crevice corrosion.

As opposed to C22, Hastelloy C276 is a nickel-molybdenum-chromium alloy that has stronger resistance to oxidising media including nitric acid and chlorine gas while offering equivalent resistance to corrosive conditions.

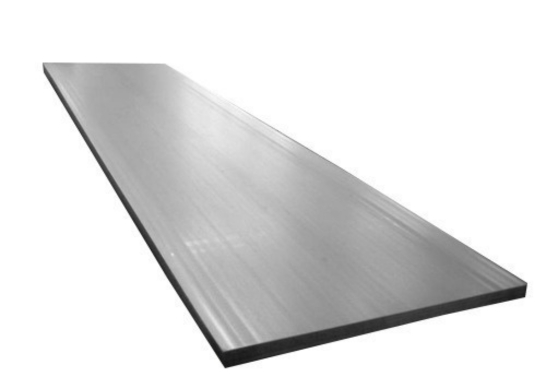

Hastelloy C22/C276 Sheet & Plates

High-performance nickel-chromium-molybdenum alloys Hastelloy C22 and C276 are renowned for their outstanding corrosion resistance, particularly in corrosive chemical conditions. For usage in chemical processing, pollution control, pulp and paper manufacture, and other industrial applications, Hastelloy C22 and C276 sheet and plates are common options.

To satisfy the needs of a particular project, Hastelloy C22 and C276 sheet and plates are offered in a range of thicknesses, widths, and lengths. They can be annealed to increase their formability and machinability after being produced commonly by hot or cold rolling.

The outstanding corrosion resistance of Hastelloy C22 and C276 sheet and plates is one of its main advantages. These alloys have excellent corrosion resistance to a variety of substances, including sulfuric acid.

Hastelloy C22/C276 Pipes

High-performance alloys like Hastelloy C22 and C276 are frequently utilised to make pipes for a variety of purposes. These alloys are perfect for usage in abrasive conditions where other materials would malfunction because of their extraordinary resistance to corrosion, erosion, and cracking.

Hastelloy C22 pipes are created from an alloy of nickel, chromium, and molybdenum with tungsten. The alloy offers outstanding protection against a variety of corrosive substances, such as sulfuric acid, hydrochloric acid, and chlorine gas. These pipes are frequently used to convey corrosive liquids and gases in the chemical processing industry.

On the other hand, Hastelloy C276 pipes are manufactured from a nickel-molybdenum-chromium alloy with tungsten and a tiny amount of iron added.