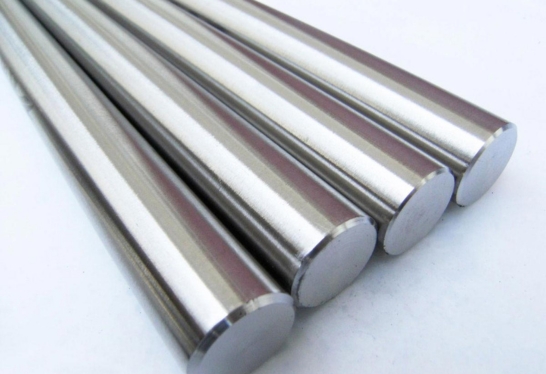

Nickel 200/201 Round Bar

The bars are produced in a wide variety with the express purpose of meeting the needs of diverse essential application requirements. Utilising high-quality nickel alloy purchased from reliable market vendors, nickel alloy 200/201 round bars are created. However, the development of technology is significantly contributing to the product's high quality.

The product is unquestionably made utilising a variety of modern tools and equipment in addition to standards for the quality of the raw materials to produce exactly what the application requires. Additionally, regular stage-by-stage inspection is carried out and is evaluated for quality control and production efficiency. The market is providing the goods in a variety of grades, specifications, and at fair prices while also taking demand and budget into consideration.

Nickel 200/201 Wire Rod

Nickel Alloy 200/201 Bars, Wires, and Rods are available in a variety of sizes from Bhansali Overseas and have great tensile strength and durability. Commercially pure wrought Nickel 200 Bars (UNS N02200) have outstanding mechanical qualities across a wide temperature range and great resistance to various corrosives, especially hydroxides. The majority of corrosive and caustic environments, media, alkalis, and acids (sulfuric, hydrochloric, and hydrofluoric) can be handled with ease by Nickel 200 Wires.

Nickel 201 Bars (UNS N02201) are used in the production of soap, viscose rayon, and other products. Nickel 201 Wires have a low work-hardening rate and low annealed hardness. We can provide our customers with these nickel alloy products in sizes and shapes that are not standard.

Nickel 200/201 Wire

Nickel 200 has excellent mechanical characteristics across a wide temperature range and outstanding resistance to many corrosives, especially hydroxides.Nickel 200 works best in reducing settings and exhibits good corrosion resistance in alkalis and acids. exceptional caustic alkali resistance up to the molten stage. The substance has excellent resistance to acid, alkaline, and neutral salt solutions, but an aggressive attack will occur in oxidising salt solutions. Can be used in temperatures as high as 550oC and is resistant to every dry gas at room temperature. It can also be used with dry chlorine and hydrogen chloride.

With qualities similar to Nickel 200 but less intergranular carbon to prevent embrittlement at high temperatures, Nickel 201 is a pure produced nickel with similar properties.It works best in reducing conditions and exhibits strong corrosion resistance in acids and alkalis. exceptional caustic alkali resistance up to the molten stage. The material has remarkable resistance in acidic, alkaline, and neutral salt solutions, but significant attack will occur in oxidising salt solutions.Useable at temperatures up to 550oC and resistant to all dry gases at room temperature in dry chlorine and hydrogen chloride.

Nickel 200/201 Wire Mesh

One of India's top producers, suppliers, and exporters of nickel alloy 200/201 wire mesh is Mannat Steel. Both nickel 200 and nickel 201 wire mesh have superior mechanical properties. With a high purity of nickel, Nickel 200 wiremesh provides good mechanical qualities and ductility. It possesses excellent electrical and thermal conductivity, magnetostrictive characteristics, and resistance to high temperature and corrosion. The main reason nickel 200 filler wire and nickel 201 wire, which has low carbon, are used, is because they have superior corrosion resistance. Compared to other nickels, strength is lower, but fracture toughness is higher. In the mining, marine, electrical, chemical, and heating industries, nickel 200 wire mesh is frequently employed as a filter or heating element. A microphone or speaker cover built of nickel 200 wire mesh can have good magnetostrictive characteristics.

Nickel 200/201 Sheet & Plates

The manufacturer and distributor of all these essential items for the industry, including Nickel 200/201 Sheets & Plates, is Mannat Steel. We satisfy all of the clients' significant needs and even provide some items that can be customised in response to demand.

The Nickel 200/201 Sheets & Plates are available with a wide range of features and specifications for customers and other dealers. The product's quality is excellent, and it was finished in accordance with global standards. In order to offer a high-quality product, the industry has a responsibility to verify every product at every stage. The mechanical property is the focus of the features, which span a large temperature range. The resistance quality is also planned in such a way as to be at its highest level. It is, nevertheless, totally rusted or corrosion protected. All of the product's edges and dimensions are flawlessly manufactured, and the design is flawless.

Nickel 200/201 Pipes

AA reputable and well-known name in the production and delivery of Nickel 200 201 Pipes & Tubes is Maant Steel. We have a long history of being a dependable company in the industry. We have been providing a variety of customers with high-quality items.

In contrast to other pipes, these ones have low electrical resistance and are ferromagnetic. As low carbon alternatives to this alloy, the pipes are not as hard as some of their rivals. The pipes have a low stiffness after annealing. They also toughen at a very slow rate. High levels of creep resistance are provided by these pipes. These pipes are very ductile and robust. At high temperatures, these pipes have better creep qualities. These pipes have outstanding oxidation resistance.