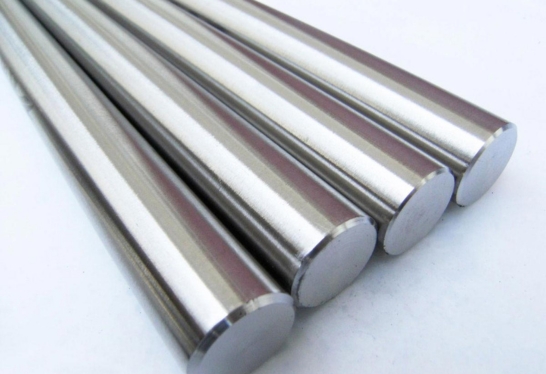

Inconel 600/601/625/800/825 Round Bar

At Ample Alloys, we have combined our practical experience and skills to create a competent product offering that ensures notable usability. We create products that are purposefully improved to satisfy market examples and requests. We produce, provide, and trade a wide selection of Inconel 600, 601, 625, and 825 Round Bars. The nickel and chromium alloys Inconel 600, 601, 625, and 825 are resistant to corrosion and high temperatures.

Many applications that call for cryogenic temperatures use nickel alloy 600, and alloy 601 offers resistance to aqueous corrosion. High calibre and resilience at high temperatures are provided by Inconel 625. Inconel Alloy 825 exhibits the same impenetrability to liquid use as Inconel Alloy 600. In addition to Inconel 601 Square Bars, Inconel 600 Bright Bars, Inconel 625Hex Bars, Inconel 825 Bright Bars, and more, we also provide UNS N06600, UNS N06601, UNS N06625, and UNS N08825 Round Bars in various forms. These WNR 2.4816, WNR 2.4851, WNR 2.4856, and WNR 2.4858 Bars are described in light of the prevailing needs of the day. We promise that every single stock is thoroughly inspected for quality. We produce items with top-notch machinery that guarantees durability.

Inconel 600/601/625/800/825 Wire Rod

NInconel 600 wire rods are known for their excellent resistance to high-temperature oxidation and corrosion, making them suitable for use in furnace components and heat exchangers.

Inconel 601 wire rods have similar properties to Inconel 600, but they also have superior resistance to oxidation at high temperatures, making them ideal for use in furnace applications.

Inconel 625 wire rods are highly resistant to corrosion and oxidation, making them suitable for use in harsh environments such as chemical processing plants and seawater applications.

Inconel 800 wire rods have good resistance to corrosion and oxidation in high-temperature environments, making them ideal for use in furnace and heat exchanger components.

Inconel 825 wire rods have excellent resistance to corrosion in a wide range of environments, including sulfuric acid and seawater, making them ideal for use in chemical processing and pollution control applications.

Inconel 600/601/625/800/825 Wire

Inconel 600 wire has excellent resistance to corrosion and high-temperature strength, making it suitable for use in chemical processing, heat treating, and furnace applications.

Inconel 601 wire has similar properties to Inconel 600, but it also has superior resistance to oxidation at high temperatures, making it ideal for use in furnace applications.

Inconel 625 wire has excellent resistance to corrosion and oxidation, making it ideal for use in harsh environments such as seawater and chemical processing plants. It is often used in aerospace and nuclear applications.

Inconel 800 wire has good resistance to oxidation and corrosion in high-temperature environments, making it ideal for use in furnace and heat exchanger components.

Inconel 825 wire has excellent resistance to corrosion in a wide range of environments, including sulfuric acid, phosphoric acid, and seawater. It is often used in chemical processing and pollution control applications.

Inconel 600/601/625/800/825 Wire Mesh

Mannat Steel and Tubes supplies and exports Inconel 601 Wire Mesh of the highest calibre. With both current and potential clients, our company has established a solid reputation for providing high-quality service and fostering working relationships.

Mannat Steel and Tubes offers high-quality, corrosion-resistant Incoloy 825 wire mesh. The UNS N08825 Wire Mesh that we offer is made up of a wide variety of alloys that exhibit great strength and high heat and corrosion resistance even under the most trying circumstances. We have provided goods to nearly 70 nations worldwide. We have amassed sufficient stock levels of all necessary commodities within our scope of supply and are in a position to provide immediate delivery because we have established ourselves and placed our warehousing facilities close to ports.

The Inconel Alloy 600 Wire Mesh supplied by Mannat Steel and Tubes is of the highest quality and has the UNS N06600 and WNR 2.4816 designations. It is available in the following forms: Inconel 600 Wire, Inconel 600 Mesh, Inconel 600 Welded Wire Mesh, Inconel 600 Woven Wire Mesh, Inconel 600 Plain Weave Wire Mesh, Inconel 600 Twill We There are many industrial applications for this Inconel 600 Wire Mesh. Mannat Steel and Tubes is a leading Manufacturer, Suppliers and Exporter of Inconel 600 Wire Mesh in various shapes such as 600 Inconel Welded Wire Mesh, 600 Inconel Woven Wire Mesh, 600 Inconel Plain Weave Wire Mesh, 600 Inconel Twill Weave Wire Mesh, 600 Inconel Dutch Weave Wire Mesh, 600 Inconel Crimped Weave Wire Mesh, 600 Inconel Three Heddled Weave Wire Mesh, 600 Inconel Five Heddled Weave Wire Mesh and more as per the clients requirments. According to national and international norms and specifications, we provide 600 Inconel Wire Mesh.

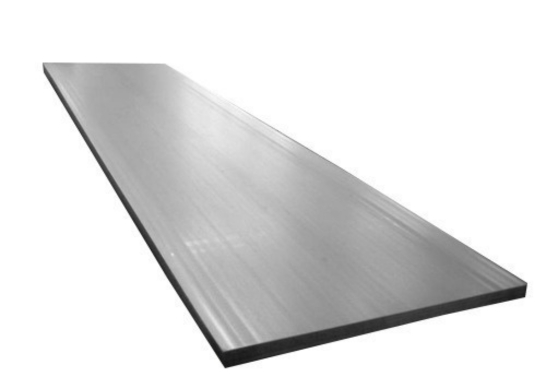

Inconel 600/601/625/800/825 Sheet & Plates

We at Ample Alloys have combined our practical experience and skills to create an excellent product line. We produce goods that are purposefully improved to satisfy customer and market demands. We manufacture, supply, and trade a range of Inconel 600, 601, 625, and 825 sheets, plates, and coils. Inconel 600, 601, 625, and 825 are nickel-chromium alloys with excellent corrosion resistance and high temperature performance.

In many applications that call for cryogenic temperatures, nickel alloy 600 can be used to a significant extent, and nickel alloy 601 has excellent resistance to water corrosion. High temperatures and higher oxidation resistance are features of inconel 625. Similar to Inconel Alloy 600, Inconel Alloy 825 also exhibits resistance to water corrosion. We provide UNS N06600, N06601, N06625, and N08825 Sheets, Plates, and Coils in a variety of forms that can be used to meet a variety of requirements. These WNR 2.4816, WNR 2.4851, WNR 2.4856, and WNR 2.4858 Plates are plotted in accordance with the prevailing conditions. We make sure that every stock is thoroughly inspected for quality. We produce items with top-notch machinery that ensures strength and longevity.

Inconel 600/601/625/800/825 Pipes

One of the leading producers of Inconel 600/601/62/5/71/8 Pipes and Tubes is Mannat Steel, which sources high-quality raw materials and ensures that its products meet the strictest industry standards for durability. A nickel-chromium alloy called Inconel 600 Pipes (Alloy 600) is used for appliances that need to resist corrosion and high temperatures. Nickel-chromium Inconel 601 Pipes (Alloy 601) are utilised for appliances that require corrosion and heat resistance. Because of its incredible strength and remarkable aqueous corrosion resistance, Inconel 625 Pipes (Alloy 625) is a nickel alloy that resists oxidation and corrosion.

A nickel-chromium-molybdenum alloy called Inconel 718 Pipes (Alloy 718) is designed to resist a wide range of severely corrosive conditions, including pitting and crevice corrosion. These pipes and tubes, which are also known by the UNS designations N06600, N06601, N06625, and N07718, can each be further customised in terms of their diameters and thicknesses in accordance with the particular needs expressed by our respected clients. Also known as WNR 2.4816, WNR 2.4851, WNR 2.4856, and WNR 2.4668, we provide the same at costs that are among the lowest in the market.