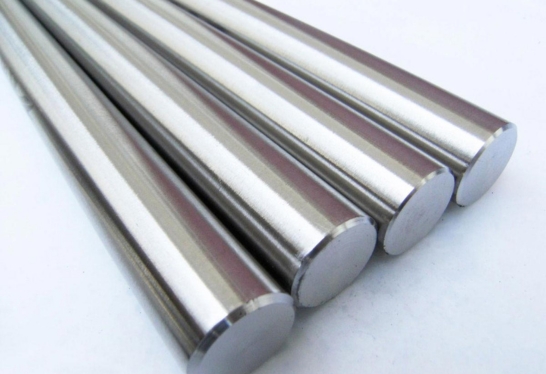

Monel 400/k500 Round Bar

A reputable manufacturer, exporter, and supplier of Monel 400 and Monel K500 round bars in India is Mannat Steel. A copper-nickel alloy called Monel K500 Rods has the same properties as Monel 400 Rods (UNS N04400). Additionally, these Alloy K500 Round Bars are stronger and harder than Alloy 400 Round Bars due to the addition of titanium and aluminium in the former. Alloy K500 Rods (UNS N05500) are an upgraded version of Alloy 400 Rods that have higher strength and resistance to corrosives, especially in seawater. Our Monel 400 Bars and Monel K500 Bars are widely utilised in a variety of application industries, including chemicals, sugar refineries, shipbuilding, paper manufacturing, and sugar mills & distilleries.

Monel 400/k500 Wire Rod

Mannat Steel provides a broad selection of Monel Alloy 400 / K500 Bars, Wires, and Rods. Our team of highly qualified engineers installs these goods using cutting-edge technology, which has been proven to be the most effective method for preventing pipeline corrosion over time. Monel 400 bars (UNS N04400) provide exceptional resistance to numerous corrosive conditions and great strength and toughness over a broad temperature range.

In some conditions, Monel K-500 Wires (UNS N05500) have a higher propensity for stress-corrosion cracking than Monel 400 Wires when they are in the age-hardened form. Additionally, we provide our customers with these monel alloy products in sizes and shapes that are customised. We also offer the same at the most competitive prices.

Monel 400/k500 Wire

Wide variety of specifications are available for monel 400/k500 bars and wire. The Monel bars are offered in a variety of dimensions, thicknesses, and shapes, including round, hex, square, and angle. In a variety of industrial applications, it is combined with other kinds. These Monel bars are often chosen due to their strong design and superior quality. They are well known for providing high-quality Monel Bars in a variety of Monel grades. Power, seawater, petrochemical, pharmaceutical, chemical, heat exchangers, gas, paper & pulp condensers, etc. are some industries that use these Bars.

A popular grade of the Monel family, Monel 400 Bars / Wire is one of the superalloys that may be formed into a variety of shapes, including hexagonal, circular, tube, wire, and others. It offers bars an excessive amount of corrosion resistance. It features a Nickel and Copper combination, which increases its corrosive qualities and gives it the capacity to perform at extremely high temperatures. These bars have high surface stability and can function even under extreme stress. It has exceptional resistance to oxidation and creep.

Monel 400/k500 Wire Mesh

A wire mesh screen with two different sets of wires interlaced at right angles is called monel 400 | k500 wire mesh. Every wire used for the warp and weft (woof/filling) passes over, beneath, or through one, two, or other numbers of wires.

According to the various inter-structures of the mesh, there are four basic weaves: plain, dutch, twilled, and twilled dutch. For instance, a simple woven wire mesh is one in which the warp and weft wires cross one another on both sides before passing underneath the next wire in line. In both directions, the warp and weft wires of twilled woven wire cloth must pass over, then under, two additional wires.

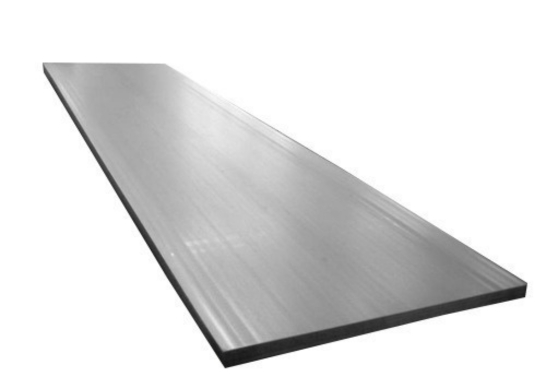

Monel 400/k500 Sheet & Plates

TThe dimensional precision and ease of installation of the Monel 400/K500 Sheets and Plates are highly regarded. In reality, the cold working procedure can quickly harden a sheet and plates. Even the product itself has good thermal conductivity and ductility. As a result, these sheets and plates are rather difficult to machine because machining depends on hardness. The product is exceptionally durable; it has a yield strength that is roughly three times higher than average and a tensile strength that is almost twice as high. And this is true even in light of other factors. It also has the quality of resistance; it is rust-resistant.

The Monel 400/K500 Sheets & Plates are used in many different sectors due to their high strength characteristics. Construction, industrial work, and the petroleum sector are the key industries that are heavily involved. The primary purchasers are primarily the metal industries, which are in charge of creating and carrying out the constructions.

Monel 400/k500 Pipes

The nickel-copper alloy used to create these pipes. In addition to having a high amount of nickel, it also has a high proportion of copper. It resists seawater and steam at high temperatures due to the robust mechanical qualities and chemical balance. This is why these pipes are used in industrial settings where processes involving high temperatures and voltage are involved. Additionally, salt solutions and caustic solutions both exhibit similar properties. Numerous physical characteristics of these pipes are influenced by nickel content. Some of the most notable are good welding capabilities, high levels of mechanical and tensile strength, and great corrosion resistance in the presence of all types of water and acids.

These pipes are renowned for having excellent mechanical characteristics even at extremely low temperatures. These pipes are durable enough to be utilised in hot environments. It is perfect because of its extraordinarily high melting point. When these pipes are in the annealed form, they exhibit poor strength. Therefore, many tempers are employed in such a situation in order to regain strength. All types of acidic solutions won't harm these pipes. In both freshwater and seawater that is moving quickly, it offers a low rate of corrosion. Along with that, it exhibits excellent resistance to corrosion cracking under the majority of demanding circumstances. Due to these qualities, it is frequently used in offshore and marine applications. These are renowned for providing extremely high resistance to alkali's effects.