Our Products

- Stainless Steel 310/310S Round Bar

- Stainless Steel 310/310S Wire Rod

- Stainless Steel 310/310S Sheet/Plates

- Stainless Steel 310/310S Wire

- Stainless Steel 310/310S Hex

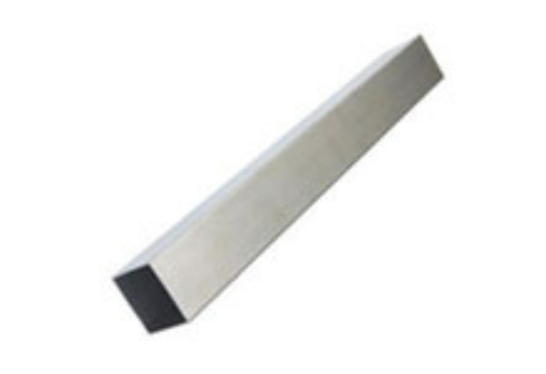

- Stainless Steel 310/310S Square Bar

- Stainless Steel 310/310S Wire Mesh

- Stainless Steel 310/310S Nut Bolt

- Stainless Steel 310/310S Fasteners

- Stainless Steel 310/310S Flat Bar

- Stainless Steel 310/310S Pipes

- Stainless Steel 310/310S Anchor

- Stainless Steel 310/310S Forging Flanges/Forging Ring

310 Stainless Steel Square Rod, Stainless Steel 310 Bright Square Rod Supplier, 310 Steel Square Rods Stockist, SS 310 Square Rod Exporter In India, SS UNS S31000 Bright Square Rods, SS 310 Square Rods Supplier In Mumbai, India.

Mannat Steel is a well-known trader, manufacturer, and exporter of SS 310 / 310S Square Bars, which are initially nonmagnetic but become slightly magnetic when cold wrought. Our Stainless Steel 310 Square Bars can withstand temperatures of up to 1150° C in continuous service and 1035° C in intermittent service. These Stainless Steel 310S Square Bars are resistant to sulfidation and can be utilised in mildly carburizing atmospheres due to their high chromium and moderate nickel content. Our SS 310 Square Bars are frequently utilised at cryogenic temperatures due to its high toughness to -450°F and low magnetic permeability. Higher alloyed stainless steels, such as these SS 310S Square Bars, provide good strength at increasing temperatures, as well as exceptional resistance to creep deformation and environmental damage. While most austenitic grades keep good strength when exposed to high temperatures, our Alloy 310 Square Bars preserve strength and toughness at sub-zero temperatures.

These Alloy 310S Square Bars are austenitic stainless steel austenitic T-300 series with a minimum of 18% chromium and 8% nickel. Our 310 Stainless SS Square Bars are not recommended for repeated liquid quenching because to the extreme thermal shock. These 310S Stainless SS Square Bars are widely used in high-temperature situations that demand scaling and corrosion resistance, as well as high temperature strength and superior creep resistance.

SS 310 Cold Finish Square Bars, Stainless Steel 310S Custom Cut Length Square Bars, SS 310 Black Square Bars, SS 310 Industrial Square Bars, SS 310S Heavy Square Bars Dimension, SS 310S Square Bars Manufacturer, 310 SS Precision Ground Square Bar in India.

Mannat Steel 310 Square Bars from Mannat Steel Corporation have a high chromium concentration, making the product medium resistant to oxidation, sulfidation, and hot corrosion. Furthermore, these products exhibit good strength when exposed to high temperatures, as do the most austenitic grades. In this case, the chosen material, Stainless steel 310, retains its strength and hardness even at sub-zero temperatures. Stainless Steel 310S Square Bars are comparable to stainless steel 304 square bars but with at least five times the carbon content.

Stainless steel 310 Square Bars have good strength at high temperatures, as well as outstanding resistance to creep deformation and environmental factors. The corrosion resistance of Stainless Steel 310S Square Bars contributes to its market attractiveness. The presence of chromium in the raw material makes the product appropriate for aqueous solutions and temperature changes. Furthermore, our products are resistant to oxidizing and carburizing environments. Mannat Steel Corporation has a team of experts and professionals who ensure raw material and end product quality. Furthermore, they monitor each stage of production to avoid errors and challenges. We source high-quality raw materials from reputable suppliers.

Stainless Steel 310 / 310S Square Bars Specification

| Dimensions | ASTM, ASME |

| Standard | ASTM / ASME SA A582, A276, A564, ASTM A484, 484M |

| Surface | hrap, hot rolled pickled or sand blasting finished, cold drawn, polished, hairline |

| Size | Tolerance: H8, H9, H10, H11, H12, H13K9, K10, K11, K12 |

Stainless Steel 310 Cold Rolled Square Bar, Stainless Steel 310S Polished Square Bars, 310S Stainless Steel Square Bars Exporter, SS 310S Hot Rolled Square Bars, SS 310 Square Rod, Stainless Steel 1.4845 Square Bars in Mumbai.

Stainless Steel 310 Square Bars are available in a variety of dimensions, standards, sizes, and surface finishes. Stainless Steel 310S Square Bars are highly resistant to most oxidizing agents, general corrosion, dyes, and a wide range of organic and inorganic compounds. These goods can be used in the presence of steam combustion gases, nitric acid, and a lower concentration of sulfuric acid solution.

Stainless Steel 310S Square Bars offers almost three times the yield strength and twice the tensile strength of carbon steel. Furthermore, these elements provide excellent stability to gamma prime formation during ageing. Stainless Steel 310 Square Bars can be used in a variety of industrial processes, including heat treatment and chemical processing.

Equivalent Grades of Stainless Steel 310 / 310S Square Bars

| STANDARD | WERKSTOFF NR. | UNS | JIS | BS | GOST | AFNOR | EN |

|---|---|---|---|---|---|---|---|

| SS 310 | 1.4841 | S31000 | SUS 310 | 310S24 | 20Ch25N20S2 | - | X15CrNi25-20 |

| SS 310S | 1.4845 | S31008 | SUS 310S | 310S16 | 20Ch23N18 | - | X8CrNi25-21 |

Stainless Steel 310 / 310S Square Bars Chemical Properties

| Grade | C | Mn | Si | P | S | Cr | Mo | Ni | N |

|---|---|---|---|---|---|---|---|---|---|

| SS 310 | 0.015 max | 2.0 max | 0.15 max | 0.020 max | 0.015 max | 24 – 26 | 0.10 max | 19 – 21 | 54.7 min |

| SS 310S | 0.08 max | 2.0 max | 1.00 max | 0.045 max | 0.030 max | 24 – 26 | 0.75 max | 19 – 21 | 53.095 min |

SS 310 / 310S Square Bars Mechanical Properties

| Density | Melting Point | Tensile Strength | Yield Strength (0.2%Offset) | Elongation |

|---|---|---|---|---|

| 7.9 g/cm3 | 1402 °C (2555 °F) | Psi – 75000 , MPa – 515 | Psi – 30000 , MPa – 205 | 40 % |

SS 310/310S Wire Application Industries

- Off-Shore Oil Drilling Companies

- Power Generation

- Petrochemicals

- Gas Processing

- Specialty Chemicals

- Pharmaceuticals

- Pharmaceutical Equipment

- Chemical Equipment

- Sea Water Equipment

- Heat Exchangers

- Condensers

- Pulp and Paper Industry